Welcome to the home of the Freedom Launcher!

Here you'll find everything you need to know about one of the biggest trebuchets around: the Freedom Launcher. Images, movies, and other information can be found at the links above, while news updates can be found below. So look around, and enjoy!

The Inaugural Launch - December 5, 2007

It was the perfect setting for the official inaugural launch of the Freedom Launcher on December 1, 2007. The day began cold and windy and just as preparations were being completed, the snow began to fall on the pasture. It was a great day for throwing.

But I shouldn't get ahead of myself. In my last update I mentioned having purchased the I beam to be used in modifying the throwing arm, and here I am talking about an inaugural launch. First things first.

The update of the throwing arm went quite well. My big concern when we started was with getting a hole cut into the steel brackets that would fit the bearing pipe just right and could be located with enough precision as to keep the throwing arm swinging relatively straight. After doing some research, I decided to order a couple hole saws from McMaster and give it a whirl. They cost about $15 total, so I figured what the heck - even if we ruin them in the four cuts required, it'll be well worth it. Ron and I were both amazed at how well the hole saws that we had only known for cutting through wood were able to cut right through the 1/4" steel I-beam, and even after getting everything done, they appeared to be as sharp as when we started. I highly recommend them to anybody looking to put a fairly accurate hole in a piece of steel. The holes weren't perfect, of course. They needed some significant deburring. But for the price, they were fantastic. We were able to keep them located quite precisely by cutting a block of wood to the width of the big green box beam that the bracket was to wrap around and using it as a guide for the hole saw. It all worked out wonderfully.

After a whole bunch of welding, the throwing arm was complete and got pushed back into place just like it had been the first time . . . and the stage was set for Ron's bachelor party. After enjoying some trap shooting in the early afternoon, the crowd moved down to the pasture for the first test launch of the revised Freedom Launcher. It was a great success. The new method of hanging the counterweight kept it swinging almost silently, and there was no sign of a freezer full of rocks flying out of control. Learning from our previous design, we fastened the bearing pipe for the main axle to the main supports with U-bolts, and we had no problem with the axle bending and working itself out of its supports as we had before. We were able to fill the freezer full of logs and rocks and the machine handled it quite well. A great time was had by all, and the Freedom Launcher was complete again.

Fast forward a month and it was time to start talking about having the official inaugural launch for those who had not been able to attend a bachelor party/test launch. A crowd was assembled, pumpkins were gathered, and in the snowy afternoon of December 1, the Freedom Launcher was unleashed. Several pumpkins, a satellite dish, our giant steel trebuchet arrow, an empty keg, and a spare tire all were among the ammunition of the day, and it was a beautiful sight. The freezer held all the wood and stones we gave it, and the projectile went higher and further. The snow was cold and wet, the wind was howling, but a long time associate of the Freedom Launcher crew, Alan Hopper, appeared on the horizon with an armful of double cheeseburgers and McChickens, and for a couple hours, everything was right. Words just can't do it justice. Check out the pictures and movies and see for yourself.

Progress, indeed - September 29, 2007

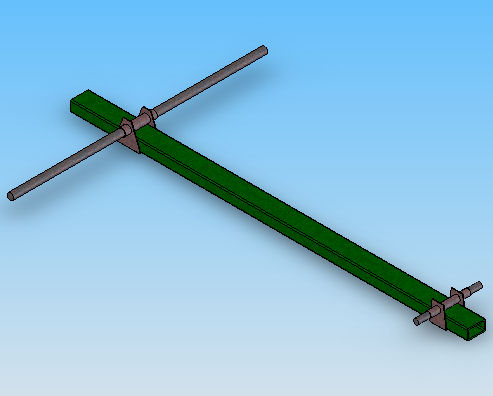

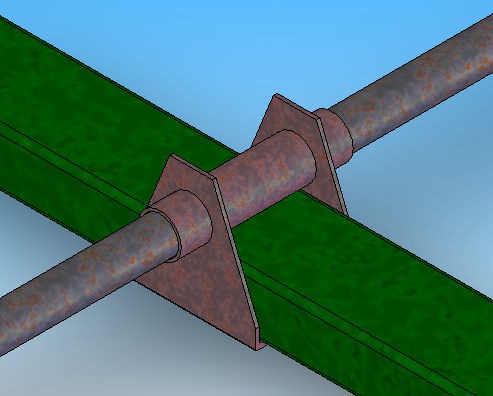

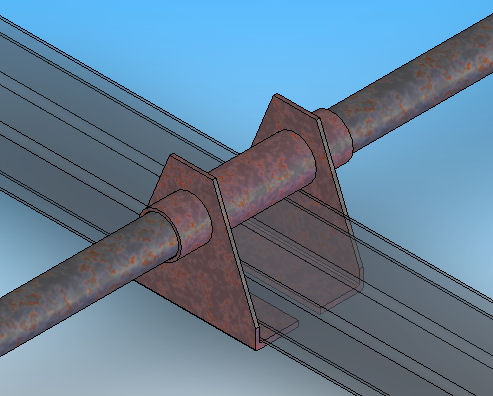

Ron and I have been getting some good design work done, and some good progress is being made, so I thought I would write a quick update to share the news. First on the list of our big news updates is that, after several months of talking about it, we finally took a trip to PAL Steel to pick up a new axle and bearing pipe. Braving one of the worst mosquito swarms in years, we picked through the amazing stockpiles of steel and found a fantastic pair - an axle of a little over 2.5" diameter and a pipe to match - 3" in outside diameter - both 8' long. It's an upgrade from the 2" axle used previously, and we're quite excited to see it in use. Ron and Rick graciously took it upon themselves to retrieve the throwing arm from the spot where we let it fall over a year ago and got the old, broken brackets removed and got the throwing arm all ready for new parts. Very nice. Finally, recall how we built the throwing arm previously:

We took a piece of angle iron and first torched a hole and grounded it out nicely and welded the bearing pipe into place. This was our critical error and the thing that broke on the first draft. Even with Kevin giving it his full attention for some time, you simply cannot create a hole that's close enough to being a circle by using a torch and grinder. Because it was uneven, the pipe had room to move around and the weld finally broke. Clearly we need a more neatly machined hole to better support the weight of the axle onto the bracket and to support a better weld. We had the idea right - fastening the axle bearing pipe to the big green beam - but our implementation was off. So, we came up with a new idea of finding some nice steel plate and cutting out a similar piece, but this time having a hole machined in with the proper tools to create a nice fit with the bearing pipe. I stopped at PAL Steel again today to get what we needed, when I was struck with a new idea. Here's what I came up with:

By using a piece of steel with an angle on it, we can hook around the bottom side of the beam for an even superior strength. So, after looking for some standard angle iron and finding that it would be impossible to find on in the required geometry, I picked out a chunk of I-beam that would work after some trimming, and called it a day. You'll also notice that we're doing something similar down on the counterweight axle. One of the big problems we had was that the way we had the counterweight hanging on the throwing arm, it had lots of room to bounce around, and that was a big problem when dealing with that much weight. By using an axle and bearing much like on the main axle, we'll nearly entirely eliminate that problem. The exact details for this aren't quite worked out yet, but you'll see them soon.

Ron is getting married and his bachelor's party is the end of October . . . we now have a timeline. Congrats Ron.

Oh, and I got married too. Yay for marriage!

No, seriously, a new website - July 7, 2007

As you'll see, work on this new site design started over a month ago in May, but I had yet to finish the Images and Movies section, and I just kept putting it off. Well, I've had another week of vacation in Michigan's wonderful Upper Peninsula, and I'm happy to report that it's done and done. Now, being out in the middle of the woods and all, I can't post this live until tomorrow evening, but it'll be up as soon as I have an internet connection. Other than that, there isn't any news on actual progress . . . Hopefully we'll have some soon. Stay tuned!

A New Website - May 31, 2007

Yes, it has been quite a while since the last update, but big things are on the horizon, and I thought it was high time I revisited the design of this website. Coincidentally, I also happen to be on a somewhat lengthy road trip between Boise and the redwood forests in California, and having my laptop with me while sitting for hours at a time, I decided there couldn't be a better time. Imagine that -- rather than sitting and playing video games, I'm here slaving away at this website.

Now, what about the trebuchet? Nothing has changed yet, but Ron and I have graduated, summer is here, and that means that the pasture will be dry and we'll have a bit more free time coming shortly. First on the list of things to do is to buy a new axle. In taking down the throwing arm last summer, we bent it up pretty bad. So, soon we'll be taking a trip over to PAL Steel to see what they might have in the scrapyard. Then, we just need to haul the throwing arm back to the shop and give it a bit of a makeover. We have some pretty good ideas as to how to beef that thing up a bit, and we figure that once we make the changes we have in mind, we'll really be able to weigh it down and get into some serious launching.

Previous Updates - Pre 2007

I don't really feel like re-formatting all the old updates, so I've kept the old homepage around for historical purposes. See them here.